Composite Panel

Composite panel is a building material made by bonding two outer layers of different materials to a core, typically made from foam, mineral, or honeycomb structures. These panels combine the strength, durability, and aesthetic flexibility of the outer layers with the lightweight, insulating properties of the core. Commonly used in construction, architecture, automotive, and industrial applications, composite panels offer benefits like excellent insulation, low maintenance, resistance to weathering, and design versatility, making them an ideal choice for both exterior and interior uses.

Composite panels are made by bonding two outer layers of material to a lightweight core. Key facts include:

- Lightweight: Easy to handle and install, reducing transportation costs.

- Durability: Resistant to corrosion, moisture, and environmental factors.

- Insulation: Offers excellent thermal and sound insulation.

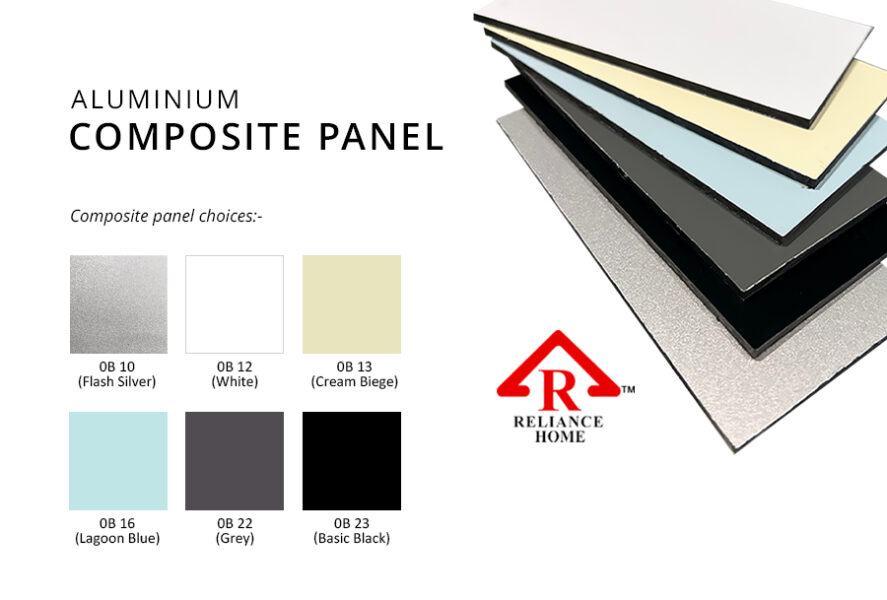

- Aesthetic Flexibility: Available in various colors, textures, and finishes.

- Strength: High strength-to-weight ratio, offering structural integrity.

- Low Maintenance: Requires minimal upkeep compared to traditional materials.

- Eco-friendly: Often made from recycled materials and recyclable.

Composite panels are commonly used in construction, architecture, automotive, and industrial applications for their versatility, strength, and energy efficiency.

For more information, ideas, design consultation, etc., please feel free to contact us now at 012-7111873

Composite panels offer several specific benefits when used in doors, making them an excellent choice for both residential and commercial applications. Here are some key advantages of using composite panels for doors:

1. Durability

- Composite panels are resistant to moisture, rot, and corrosion, making them a durable option for doors, especially in areas with high humidity or fluctuating weather conditions. They can withstand the test of time without deteriorating easily.

2. Lightweight

- Despite their strength and durability, composite panel doors are lightweight, which makes them easier to handle and install compared to traditional wooden or metal doors.

3. Insulation

- Composite panel doors typically provide excellent thermal and sound insulation. They help maintain a comfortable temperature inside the building by preventing heat loss or gain and can reduce external noise.

4. Low Maintenance

- Composite panel doors require minimal maintenance. Unlike wood, they do not need regular sanding, sealing, or painting, which saves time and effort over the door’s lifespan. They also resist fading and warping over time.

5. Aesthetic Variety

- Composite panels can be manufactured in a variety of colors, textures, and finishes to suit different design styles. Whether you prefer a wood-like appearance or a more modern, sleek design, composite panel doors offer flexibility in aesthetics.

6. Enhanced Security

- Many composite panels are designed with internal reinforcement, making them more secure than traditional wooden doors. The strong structure can provide better resistance against forced entry.

7. Eco-friendly

- Many composite panel doors are made from recycled materials or sustainable resources. This makes them an eco-friendly option compared to solid wood doors, which can contribute to deforestation if not sourced responsibly.

8. Weather Resistance

- Composite doors are resistant to harsh weather conditions, including rain, snow, and extreme temperatures. Unlike wood doors that can swell, crack, or warp, composite doors maintain their integrity and appearance over time.

9. Fire Resistance

- Some composite panel doors are made with fire-retardant properties, which can add an extra layer of safety to buildings, especially in commercial or industrial applications.

10. Cost-Effective

- Composite panel doors tend to be more affordable than high-end wooden doors while offering similar or superior durability, insulation, and aesthetics. This makes them a cost-effective choice for a wide range of applications.

SGS TAIWAN LTD

(SHS is the world’s leading inspection, verification, testing and certification company)

Test Result (Pattern PS Sheet)

| Property | Test Method | Test Result |

| Tensile Strength (MPa) | ASTM D638 | 30.7 |

| Elongation at rapture(%) | ASTM D638 | 6.2 |

| Specific Gravity (gm/cm) | ASTM D792 | 1.05 |

| Haze | ASTM D1003 | 6.35 |

| Shrinkage (%) | ASTM D4802 | 2.49 |

| Water Absorption (5)(23*C 24 Hours) | ASTM D570 | 0.01 |

| Heat Distortion Temperature (*C) | ASTM D648 | 93.4 |

| Thermal Stability | ASTM D4802 | Bubbies or blisters |

| Impact Strength Izcd (J/m) | ASTM D256 | 13.1 |

| Light Transmittance (%)(400-700m) | ASTM D1003 | 89.2 |